Case History: Concrete Installation

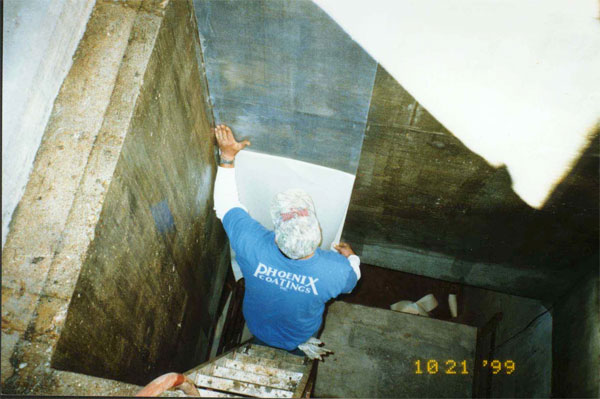

The following study illustrates the use of Integument’s new FluoroGrip ® peel-and-stick fluoropolymer films for preventing corrosion and providing a low energy release surface on a corrosive vent shaft.

The concrete was first primed prior to FluoroGrip ® installation. Inspection is facilitated by priming with Integument’s CP-300 Conductive Epoxy Primer. Traffic areas are protected by applying a chemical resistant topping.

System Lay-Up

4″ cap strips of 2 mil FluoroGrip ® – M (MFA), treated on two sides and laminated with acrylic adhesive, were used at the corners of the chute and where two sections of FluoroGrip ® – M (MFA) were butted against each other.

Since the film is non-toxic and does not emit fumes, the installer is not required to wear any protective equipment or clothing to install FluoroGrip ®.

24″ rolls of 10 mil FluoroGrip ® – M (MFA), laminated with acrylic adhesive, were used to coat the 140 square foot surface.

Hand tools were used to facilitate bonding between the acrylic pressure sensitive adhesive and the primed concrete surface. Adhesive bonds immediately with maximum adhesion achieved in 24 hours.

Completed FluoroGrip ® installation with no hazardous wastes generated.

- FluoroGrip ® – M is best suited where temperatures reach 450° F and extreme chemical or other exposures occur.

* MFA is a copolymer of tetrafluoroethylene and perfluoromethylvinylether. MFA is structurally and functionally similar to perfluoroalkoxy fluoropolymer (PFA).

- FluoroGrip ® – E is the right choice for exposures to 325° F and / or in abrasive situations.

*ECTFE is a copolymer of ethylene and chlorotrifluoroethylene.

Product Standards

Standard Roll Widths: 6, 12, and 24 inches

Standard Lengths: 20 and 40 feet

Standard Thickness: 2, 5, 10, and 20 mil

Special Roll Widths: 1 to 48 inches

Standard Roll Widths: 1, 2, and 4 inches

Standard Length: 30 feet

Standard Thickness: 2, 5, and 10 mil

Disclaimer: The information printed herein is furnished free of charge and is based on technical data that Integument Technologies, Inc. believes to be reliable. It is intended for use by persons having technical skill, at their own discretion and risk. The handling precaution information contained herein is given with the understanding that those using it will satisfy themselves that their particular use conditions present no health or safety hazards. While the information contained herein is believed to be correct, Integument Technologies, Inc. makes no representation as to the accuracy of it. Since the conditions of product use are beyond our control, Integument Technologies, Inc. assumes no liability in connection with any use of this information. The evaluation of the product described herein under end-use conditions prior to specifications is essential. Nothing contained herein is to be taken as a license to operate under or as a recommendation to infringe any patents.